Time Savings and Data Consistency: The Spare Parts Lists for DANA SPICER

Background information

Kittelberger recently automated the production of spare parts lists for DANA SPICER. All marketing and product data have been managed and structured for several years using the advastamedia® suite. It was therefore a logical next step to generate the spare parts lists through the system as well—resulting in significantly faster and more visually appealing output.

Key data

- Customer: Victor Reinz / Dana Spicer

- Section: Database Service and Support, Electronic / Database Publishing

- Launch: July 2024

Previous Situation

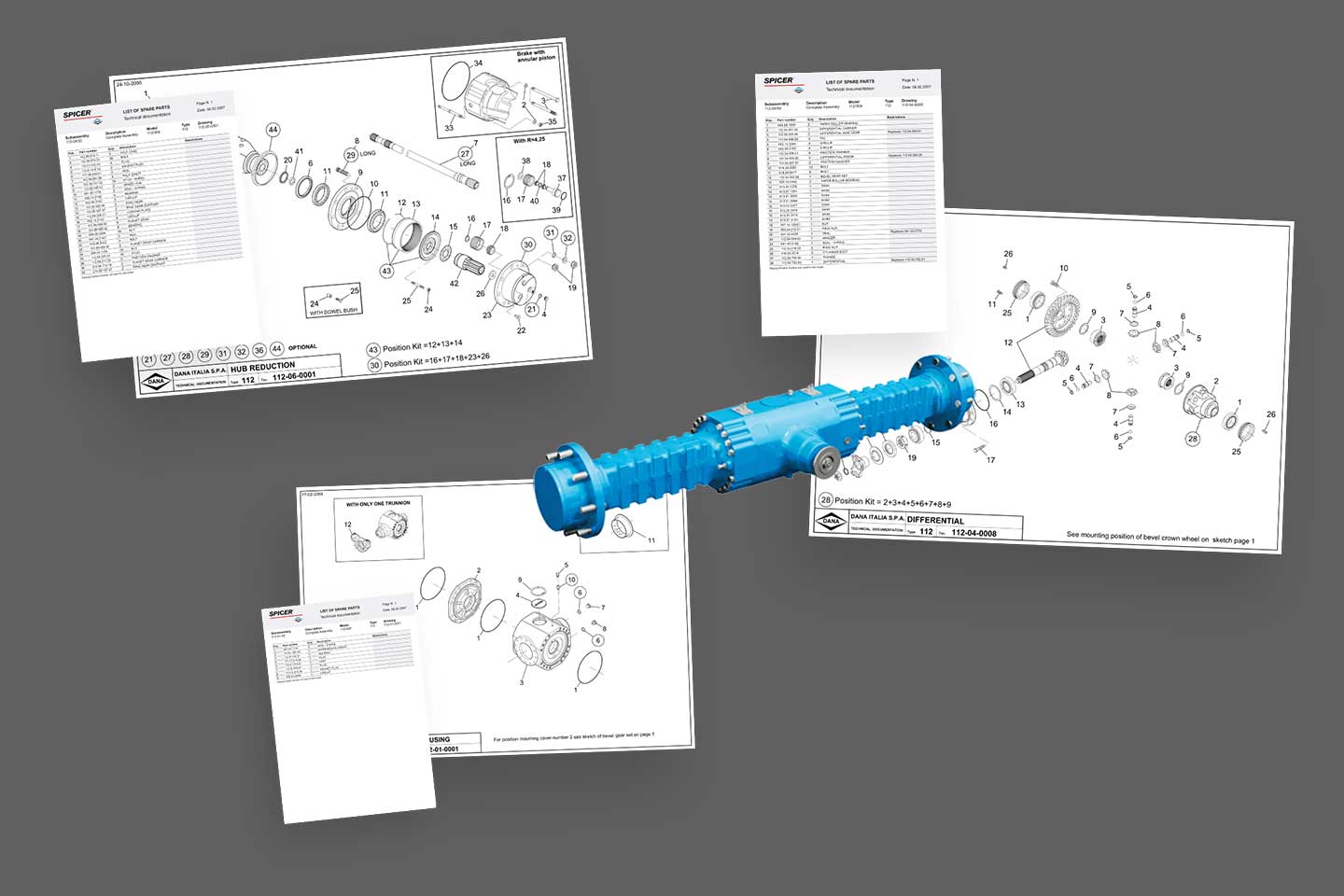

To provide customers, partners, and internal sales teams with accurate information, DANA SPICER maintains spare parts lists. These lists document which parts belong to which model, taking into account factors such as model series, submodels, and other parameters. The output typically includes PDFs, structured Excel files, and exploded-view drawings organized in a defined folder structure.

Up to now, creating these spare parts lists was a time-consuming process – involving multiple tools, several team members, and often inconsistent availability of the necessary data.

The Solution

DANA has been using the Kittelberger advastamedia® suite for many years to manage and structure product information. The print catalog and other media outputs are already generated using this system.

It was therefore a logical next step to also integrate and automate the generation of spare parts information within the same system.

Project Overview and Outcome

The first step involved implementing data collection within the system. All required technical data from the models, their linked submodels, and the associated spare parts were collected and output as structured XML.

Next, a program logic was developed that uses the collected data to generate a PDF-format spare parts list, export structured Excel data, and retrieve all relevant exploded-view drawings. This logic now documents and automates steps that were previously handled manually. The result: time savings, production reliability, and significantly improved data consistency.

“This is another one of those projects where automated output enhances the system by feeding it faster and more accurate data – a win for everyone involved!” says Daniela Haid, Head of Digital Services at Kittelberger, who led the project.

And that’s not all: the automation also brought visual improvements. The spare parts lists now automatically include a cover page, version numbers, and other metadata to simplify storage and document management.

About DANA SPICER

As a global leader in innovative axle technologies, Dana offers a full range of the most efficient light-, medium-, heavy-duty, and specialty drive axles for commercial vehicle applications. Its unique combination of patented technologies and engineering solutions ensures durability, low maintenance, and long-lasting axle performance.